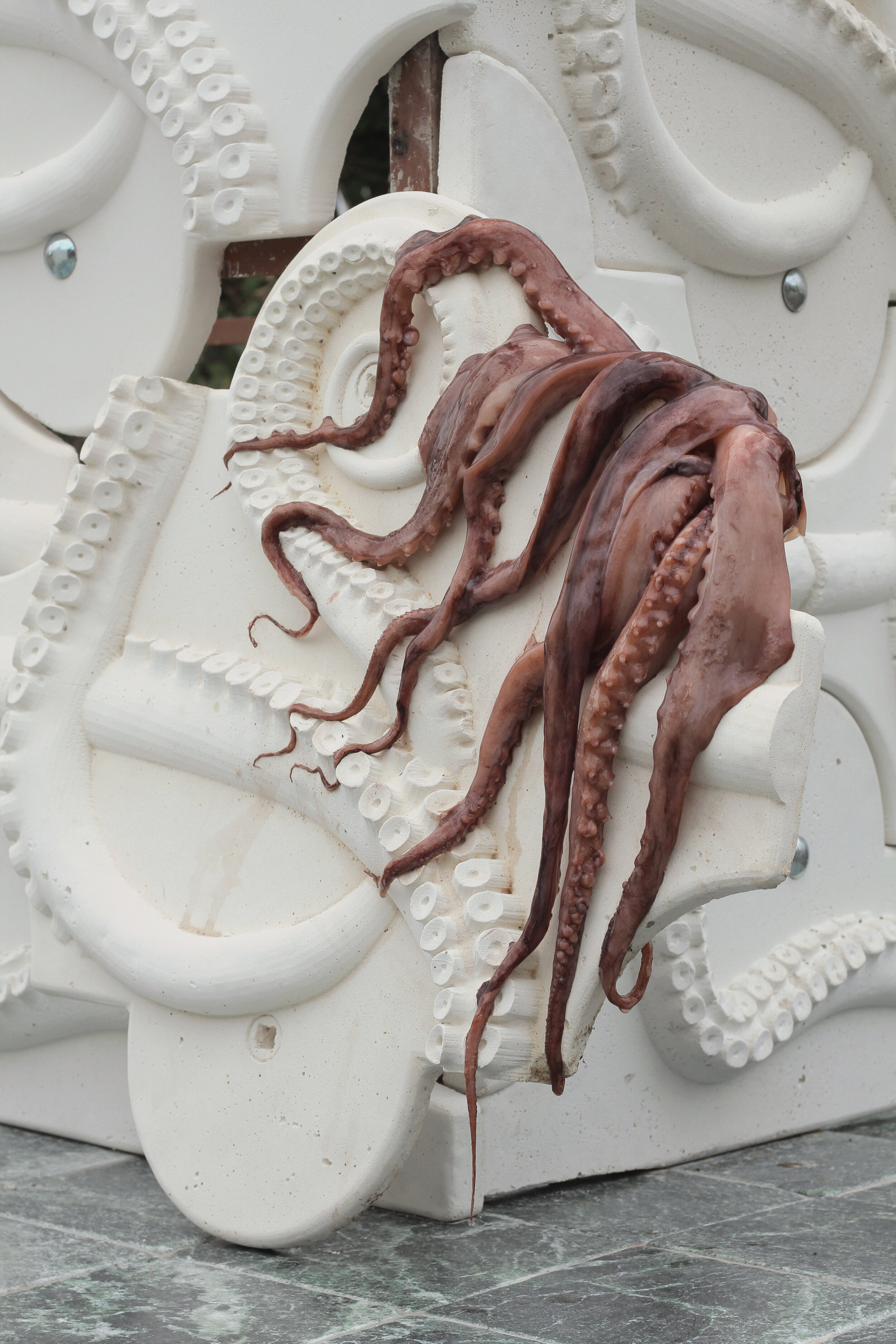

KRAKEN WASHED ASHORE

Digitally fabricated ornamental design

After finishing Third Year, I built a staircase flanked by two ornamented columns in my mother’s garden in France. I built everything by hand thus learning a lot about project management and fabrication.

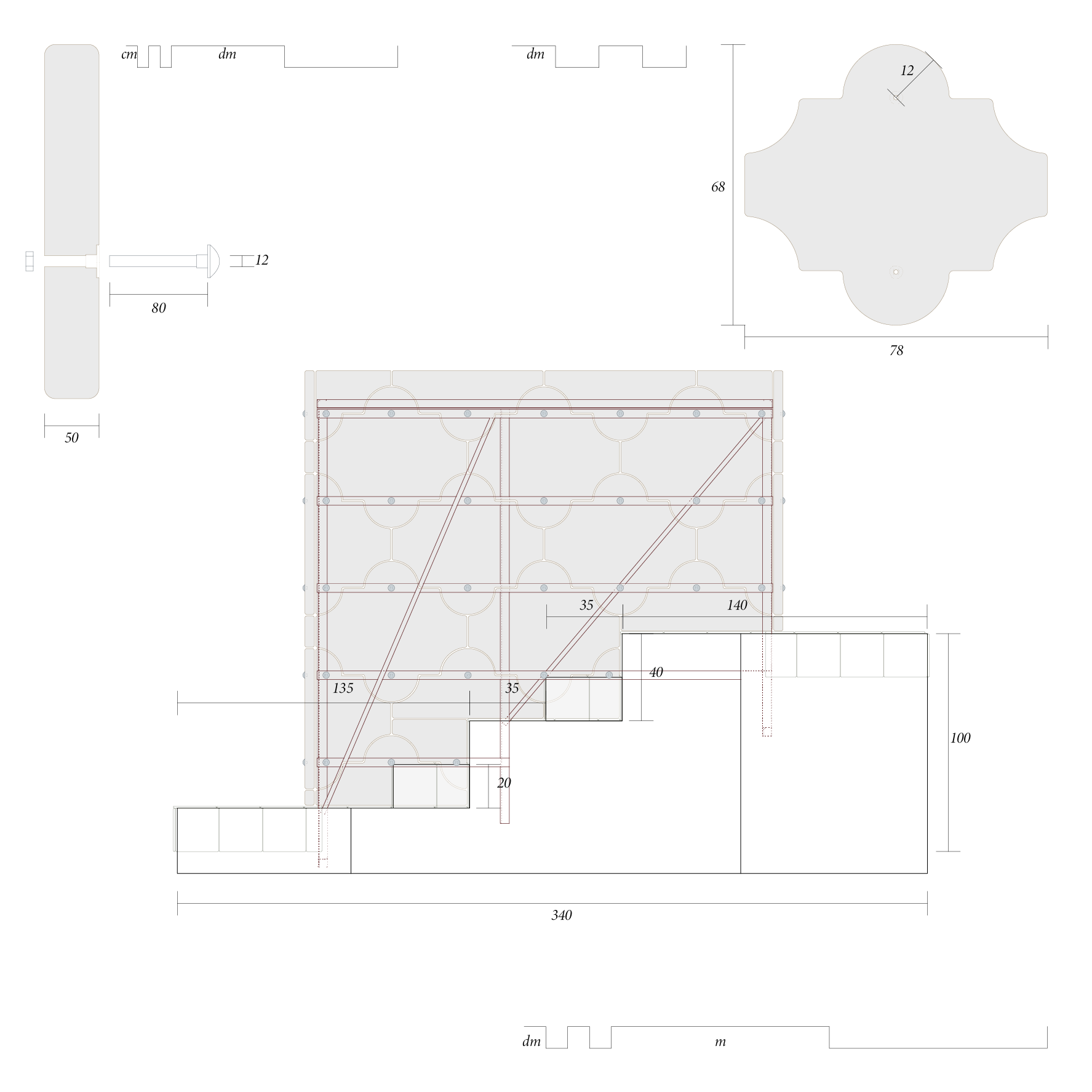

Wanting to explore ornament by digital fabrication, I started developing a octopus themed pattern that would fit onto the columns. To keep the amount of different tiles to a minimum, I made sure bottom and top and left and right was the same. It required thickness of the tentacle to be the same thickness and the sucker cups pointing outwards at all the seams.

The tiles where designed in 3ds Max where by using instancing I could easily edit the pattern with live-updating copies. The resulting meshes where sent to the digital prototyping lab at the Architectural Association where I was studying at the time. Using a large CNC machine, the tiles where cut out of hard foam which were subsequently sent to France. There I created silicone moulds for the tiles. The tiles where cast using white cement and a local fine sand. The resulting tiles reveal all stages of their creation from subtle lines showing the polygons, tracks from the 6mm drill-bit of the CNC and air bubbles from the casting.